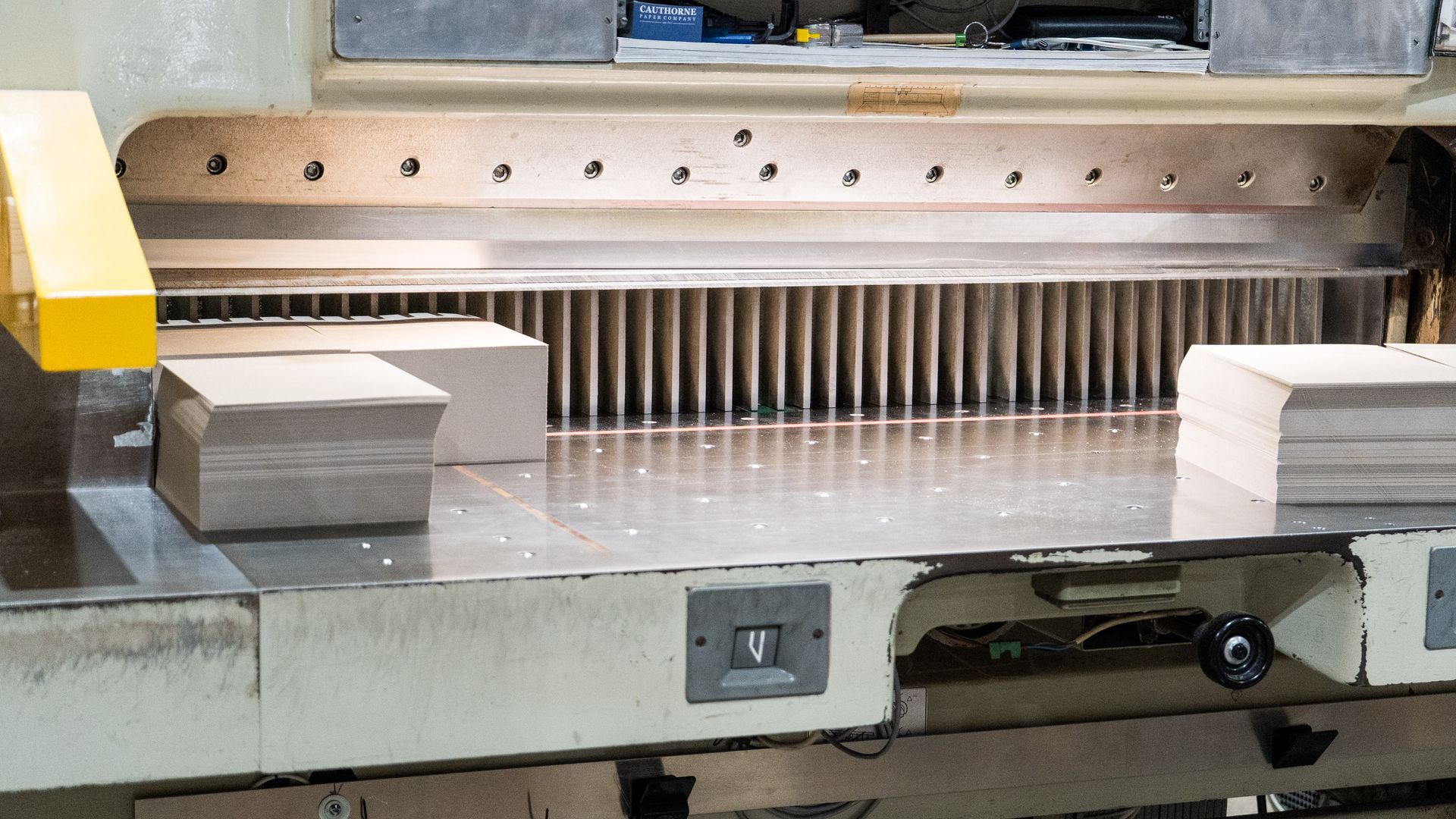

The Art of the Precise Cut: Showcasing Unrivaled Accuracy

July 18, 2025

The Art of the Precise Cut: Showcasing Unrivaled Accuracy

At Cauthorne Paper, "precision" is more than a buzzword; it is the very essence of our craft. It signifies a meticulous, highly controlled process that transforms wide master rolls of flexible material into narrower, perfectly dimensioned widths, utilizing state-of-the-art shear slitting equipment. This foundational operation is critical for preparing materials, whether for subsequent converting processes or for producing finished roll stock ready for immediate distribution or assembly. Our unwavering commitment to precision means achieving exact specifications, maintaining consistent quality, and adhering to the exceptionally tight tolerances that are paramount for high-performance downstream manufacturing applications.

The level of accuracy we achieve in precision slitting is truly remarkable. For the most specialized applications, such as narrow width slitting, our capabilities extend to tolerances as low as ±0.004 inches, producing widths as narrow as 0.375 inches. This exacting standard is indispensable for applications demanding precise measurements, particularly within critical industries like automotive and aerospace.

Human oversight remains vital; our specialists meticulously check machine work, ensuring that the speed and efficiency of automation are harmoniously blended with the unparalleled quality traditionally associated with hand-work. This dedication is reinforced by regular inspections and strict adherence to rigorous quality control standards, integral to maintaining this high level of precision throughout every stage of the slitting process.

The ability to consistently achieve such fine tolerances makes precision slitting a foundational element for high-performance end products, directly influencing their functionality and safety. When slitting is executed with this level of exactness, subsequent manufacturing steps proceed seamlessly, minimizing complications. This proactive approach prevents defects, significantly reduces the need for costly rework, and ultimately guarantees the reliability and performance of the final product. For critical applications, be it components for aerospace systems or intricate medical implants, the exactitude provided by precision slitting directly translates to enhanced safety and operational integrity. Thus, at Cauthorne Paper, precision slitting transcends being merely a cutting service; it stands as a critical enabler for advanced manufacturing, underpinning the quality and reliability of complex assemblies.

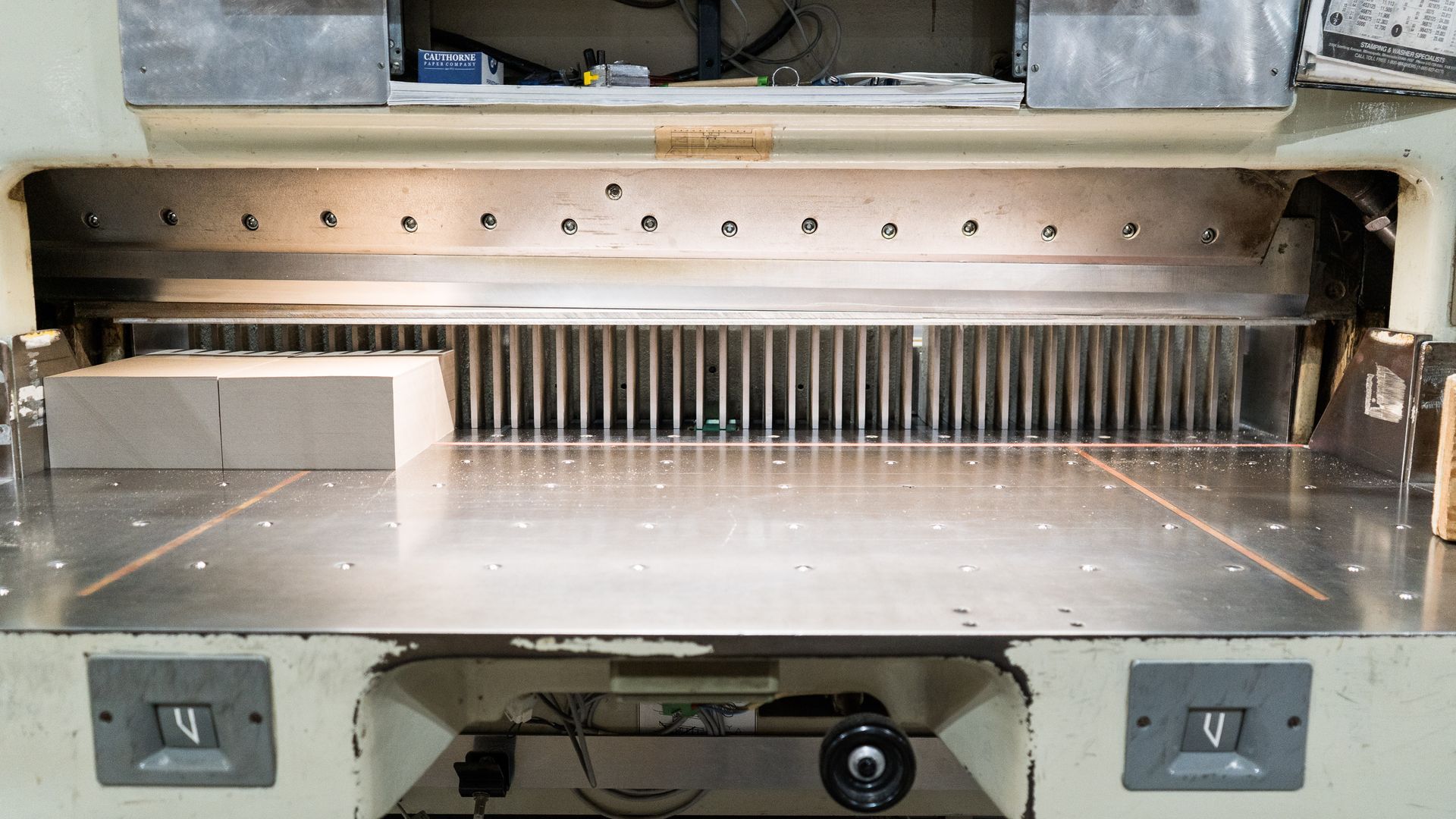

The Unseen Heroes: How Slitting Transforms Raw Materials into Flawless Components

Precision slitting, while often operating behind the scenes, plays an indispensable role in the manufacturing supply chain. It is the transformative process that converts bulky, wide master coils into the exact, high-quality narrow strips essential for diverse production processes. Our slitting lines serve as the backbone of this conversion, reshaping wide coils of material into narrower strips precisely tailored for applications ranging from automotive components to consumer goods. This process fundamentally turns large, unwieldy rolls into manageable strips, significantly simplifying handling, storage, and transportation for our clients.

A key advantage of Cauthorne Paper's precision slitting services is its profound impact on material optimization and waste reduction. By converting large coils into narrower strips with exceptional accuracy, our process maximizes material usage and minimizes waste. Customizing strip widths allows manufacturers to significantly reduce waste and optimize material utilization, directly translating into substantial cost savings. This meticulous approach also leads to a notable reduction in scrap material generated during production.

Operational efficiency is also dramatically improved. Precision slitting facilitates quicker production times and reduces downtime by minimizing the need for adjustments. The accuracy of a slit roll extends beyond just its width; clean edges, consistent tension, and controlled winding are crucial elements that further minimize waste, prevent defects, and ensure that production lines operate efficiently and continuously.

This process is a core driver of lean manufacturing principles and supply chain efficiency, directly contributing to cost savings and a faster time-to-market. The benefits of reduced waste, increased speed, and easier material handling are fundamental to achieving operational excellence. By optimizing material use and streamlining handling,

precision slitting directly lowers operational costs through less scrap, reduced inventory, and faster throughput. This also enhances overall supply chain responsiveness, allowing companies to implement and benefit from just-in-time inventory management. The transformative power of precision slitting positions it not merely as a processing step, but as a strategic tool for achieving operational excellence and maintaining cost competitiveness.

Ready to work with Cauthorne Paper?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 804-798-6999

Agency Contact Form

More on Paper

The Rollout