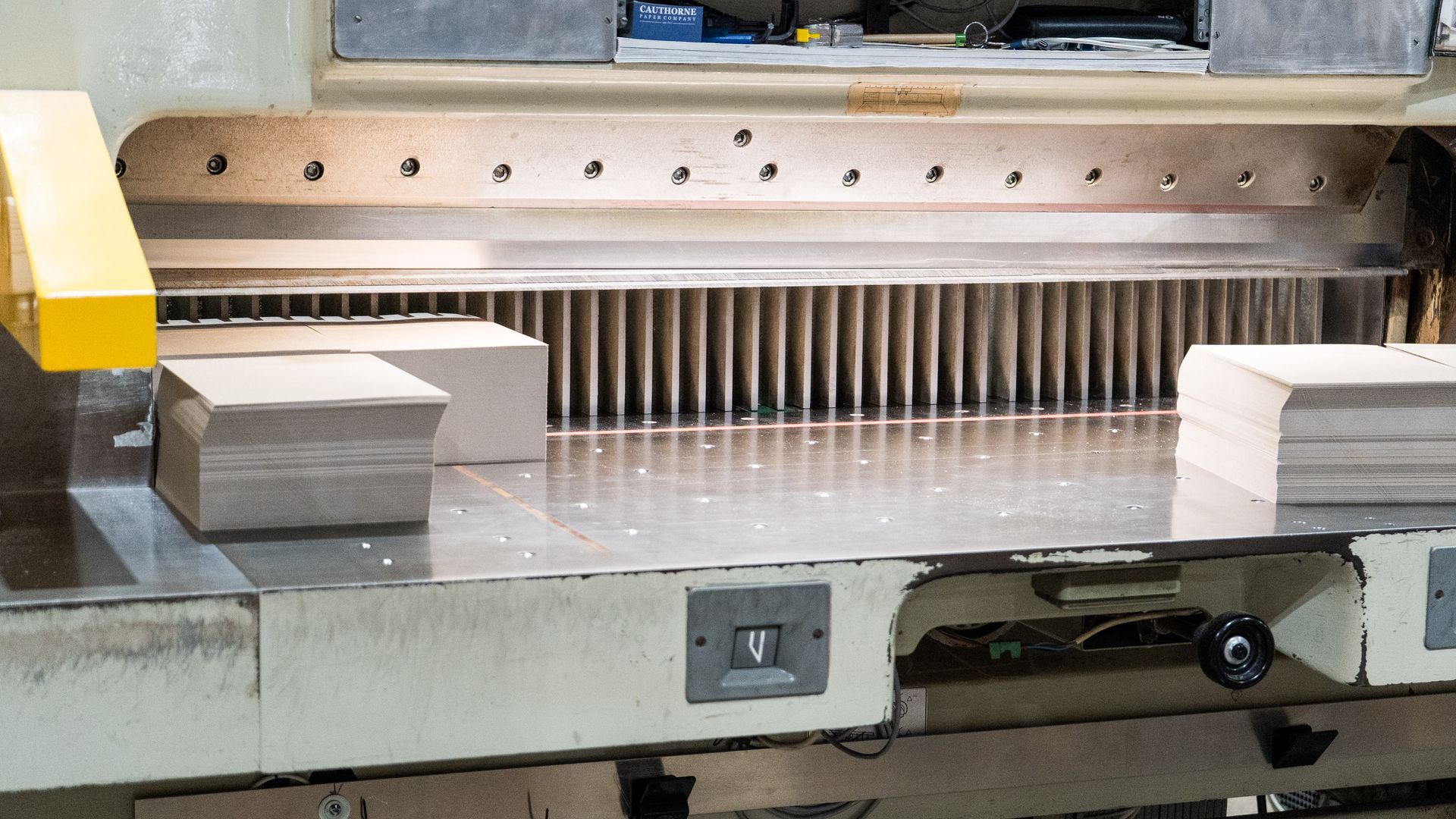

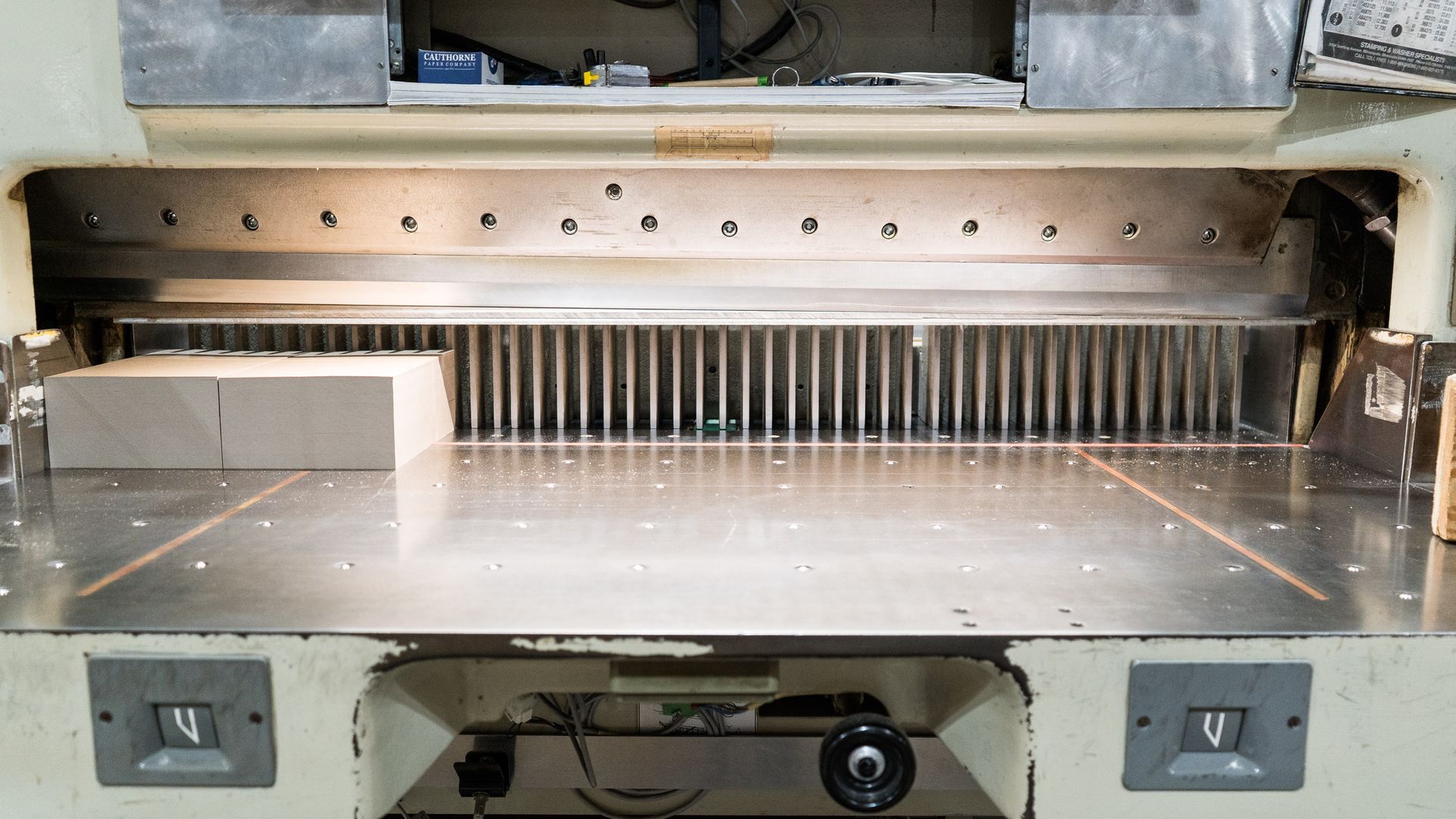

Precision Slitting Services: Unrivaled Accuracy for Your Materials

The Cauthorne Advantage: Why Our Precision Slitting Services Stand Out

At Cauthorne Paper, our precision slitting services transform wide rolls of material into precisely specified narrower widths, often with micrometre-level accuracy. With over a century of expertise in paper converting, we ensure your materials are perfectly prepared for their next stage, whether for packaging, printing, or manufacturing.

Our precision slitting service offers distinct advantages that directly translate into improved operational performance and cost efficiencies for your business:

Unmatched Accuracy:

We deliver consistently precise roll widths with clean, burr-free edges and minimal material deformation. Our machine achieves exceptionally tight tolerances, down to 0.004 inches.

Enhanced Efficiency:

Precisely slit rolls are narrower and easier to handle, store, and feed into automated manufacturing equipment. This improved manageability translates into increased operational speed and accuracy, facilitating quick turnarounds.

Material Optimization:

By precisely cutting materials to exact dimensions, our precision roll slitting services inherently minimize scrap and maximize material yield, leading to substantial cost savings and supporting your sustainability goals.

Industry Expertise:

With over a century in the paper converting business, we bring unmatched knowledge and craftsmanship to every project.

Our Comprehensive Precision Slitting Capabilities

Cauthorne Paper's capabilities extend across a broad spectrum of materials and employ advanced slitting methodologies to meet diverse client needs with the highest degree of precision and efficiency.

Materials Converted

While specializing in various paper types such as Kraft Paper, Linerboard, and Printing Papers , our expertise also encompasses a wide range of flexible materials, including:

- Films: Medical-grade films, PET, PVC, polyester polyolefin, HDPE, polypropylene, and other specialty films.

- Other: Nonwoven and certain woven fabrics, Laminates, Coated Substrates, Barrier Films, Foams, Sponge, Cork, and Rubber.

Advanced Slitting Methods

We utilize a range of advanced slitting technologies, with the optimal method selected based on your material characteristics, desired edge quality, and tolerance requirements:

- Shear Slitting: Ideal for heavier or more abrasive materials, producing clean, burr-free edges.

Beyond Slitting: Your Strategic Partner

Beyond precision slitting, Cauthorne Paper offers a suite of value-added services designed to streamline your supply chain, enhance product quality, and reduce time to market :

Industries Commonly Served

Paper Distributors

Reliable paper grades and custom converting services to support your distribution needs.

Cold Chain Supply

Durable, moisture-resistant paper products tailored for temperature-sensitive logistics.

Blade Manufacturing

Precision-cut substrates and interleaving materials designed for blade production and packaging.

Pesticide (Chemical Manufacturing)

Chemical-resistant papers and custom solutions for secure product containment and labeling.

Performance Fibers (Non-woven Textiles)

Paper materials engineered for strength, compatibility, and seamless integration with non-woven processes.

Packaging & Manufacturing

Versatile paperboard and converting services optimized for industrial packaging and production lines.

Partner with Cauthorne Paper for Precision and Performance

Choosing Cauthorne Paper means partnering with a leader in precision slitting services. Leverage our century of experience, well-equipped machinery, and unwavering commitment to quality to optimize your operations, reduce costs, and gain a significant competitive edge.

Contact us today to discuss your specific material converting needs and discover how our precision slitting solutions can benefit your business.

The Rollout